A rotary table is a versatile machining tool used in metalworking, specifically in milling and drilling operations. It allows for the precise positioning and rotation of workpieces to facilitate cutting, drilling, and milling at various angles and orientations. Rotary tables come in different configurations, including horizontal and vertical types, each with its own set of features and applications.

Horizontal Rotary Table:

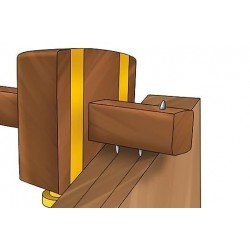

- A horizontal rotary table is designed to be mounted horizontally on the milling machine's worktable.

- It rotates around a horizontal axis parallel to the table surface.

- Workpieces are typically mounted directly on top of the rotary table or attached to fixtures secured to the table surface.

- Horizontal rotary tables are commonly used for machining operations such as milling slots, holes, and other features on cylindrical or disk-shaped workpieces.

Vertical Rotary Table:

- A vertical rotary table is mounted vertically on the milling machine's spindle or on a vertical machining center.

- It rotates around a vertical axis perpendicular to the table surface.

- Workpieces are often clamped to the rotary table's surface or attached to fixtures mounted on top of the table.

- Vertical rotary tables are frequently used for machining operations that require angular or tilted features, such as cutting bevels, chamfers, and angled holes.

Both horizontal and vertical rotary tables offer advantages depending on the specific machining requirements:

Horizontal Rotary Tables: These tables are ideal for machining operations where the workpiece needs to be rotated around a horizontal axis parallel to the machine's worktable. They are well-suited for tasks such as cutting circular profiles, grooves, and slots.

Vertical Rotary Tables: These tables are preferred for machining operations that involve angular or tilted features, allowing for precise positioning and cutting at various angles. They are commonly used in applications such as gear cutting, indexing, and machining complex contours.

In summary, the choice between horizontal and vertical rotary tables depends on factors such as the type of machining operation, the orientation of the workpiece, and the desired cutting angles. Both types of rotary tables contribute to the versatility and efficiency of milling and drilling processes in metalworking industries.

- Stock: In Stock

- Model: GMT-0213